February 21st, 2017

PowerCalc™ won Gold in Consulting-Specifying Engineer’s annual contest for Product of the Year 2016.

Our last newsletter discussed the 7 reasons for winning: the power of (1) the PowerCalc algorithm, (2) the PowerCalc panel, (3) the PowerCalc process, (4) PowerCalc for NEC compliance, (5) the PowerCalc Wizard, (6) PowerCalc in the cloud, and (7) the PowerCalc experience.

Let’s discuss Reason #2 in more detail: the PowerCalc panel.

PowerCalc’s Panel is the Design Engine

It sounds like a common issue: all electricals use panels for their work every day on every project. Each engineering firm has its own panel style. Other software programs use the panel too, but their uses are generally passive as placeholders for data, simple mathematical calculations or power system analysis.

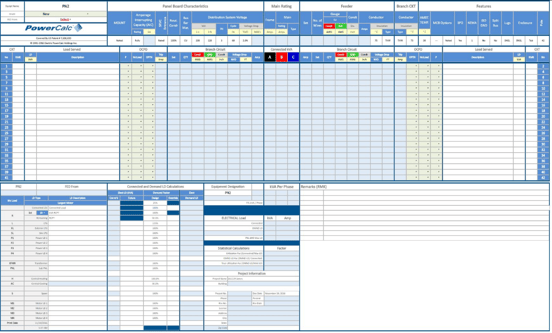

In contrast, PowerCalc makes the panel center stage: the engine to design the entire power distribution system in a facility. Each cell on each of PowerCalc’s panels is packed with algorithms communicating with its proprietary database. Panel

Simple “place holding” or even tabulation is replaced with a software system that integrates 7 million + calculations across the design. To see all the inputs/outputs: Inputs/Outputs

PowerCalc has 5 standard forms: (1) Branch Circuit Panel; (2) Distribution Panel and (3) Main Distribution Panel; as well as (4) Equipment Schedule and (5) eNODE™. All calculations are integrated across these forms to document and design the power distribution system. Panel

Main Distribution and Distribution Panel Boards: main feeder conductor and conduit size, ampacity, over current protection device (OCPD), main feeder size, voltage drop and equipment grounding conductor and grounding electrode Conductor.

Main Distribution and Distribution Panel Boards: main feeder conductor and conduit size, ampacity, over current protection device (OCPD), main feeder size, voltage drop and equipment grounding conductor and grounding electrode Conductor. Branch Circuit Panel Board: conductor and conduit size, ampacity, over current protection device (OCPD), voltage drop and round conductor.

Branch Circuit Panel Board: conductor and conduit size, ampacity, over current protection device (OCPD), voltage drop and round conductor. Building Equipment Schedule: electrical characteristics of each branch circuit, size of the over current protection device (OCPD) (fuse or circuit breaker), conductor size and the electrical enclosure frame size and characteristics.

Building Equipment Schedule: electrical characteristics of each branch circuit, size of the over current protection device (OCPD) (fuse or circuit breaker), conductor size and the electrical enclosure frame size and characteristics. eNODE™: tracks general information about the project and maps the entire power distribution system aggregating information from the panels, modules and schedules and determining connectivity and power flow.

eNODE™: tracks general information about the project and maps the entire power distribution system aggregating information from the panels, modules and schedules and determining connectivity and power flow.

This integration means that you can input values on different panels, schedules or even the eNode, and electrical values are automatically populated across the design/on all the forms.

Branch Circuit Panelboard

Take a look at PowerCalc’s Branch Circuit Panelboard. It is very familiar and intentionally mirrors the panelboard/panel box installed by the electrical contractor in the building. This utilitarian feature promotes the easy and accurate installation of electrical equipment.

“Family Connections”: the Hierarchy

A key part of the power distribution design is connecting the panels and preserve the voltage Hierarchy.

A. Parent Child

Whether the Parent Panel and the Child Panel are at the same or different voltage levels, PowerCalc allows the connection. If the two panels are at the same voltage level, then the eNODE acts as a traffic cop making the connection and passing the load from the Child Panel to the Parent Panel upstream directly.

But if the Child Panel is at a lower or higher voltage than the Parent Panel, the eNODE allows the connection and passes the load through a step down transformer or a step up transformer respectively.

PowerCalc automatically sizes the transformer kVA along with the associated primary and secondary feeders.

B. Twin PanelsThis is the connection known as “Fed Thru” or “Double Lugs” connections in the ind ustry.

ustry.

Whether Fed Thru or Double Lugs, PowerCalc considers these “twins” as one eNODE and performs all calculations including the demand load calculations as a single Panel.

C. Brother-Sister

This is the connection known as “Sub Fed” or “Sub Panel”.

For details on all and each of the panels, including their organization and functionality, see our just released User Manual: Chapter Two: PowerCalc Architecture.

Why is the panel as a calculation engine important?

PowerCalc automates the electrical design process.

It is well established that automation is the driver in our tech-centric society and business world. Save Time/Save Money

Automation drives productivity across all businesses, large or small. Changes, even small ones, over time snowball into massive gains in productivity.

It includes: automation of processes with databases, standards, and updated procedures resulting in fewer errors, fewer building department comments and fewer issues with finished designs, And, just less time spent on design and repetitive calculations.

To illustrate this point, we’ve put together the illustration above, a chart focused just on design time. It shows how PowerCalc streamlines the design process to save days of engineering man hours.

Let me know what you think…and in our next issue we’ll talk about the power of PowerCalc’s process. Also, be sure to sign up for our blog.

James

James Khalil, P.E.

Inventor of PowerCalc

(561) 271-5643

488 N. Federal Hwy, Boynton Beach, Florida 33435

(561) 278-9969

Inbound Performance Template by SmartBug Media. Copyright 2026.

All Rights Reserved